Instructions for installing the "jaak hack" Paddle Shifter Wiring Harness, as supplied by plcman.

Included are instructions for the simple adapter board kit, but soon I should be able to add instructions for the lockout and line-lock kits.

UPDATE: Here's the link to my Paddle Install thread, with info on all the steering wheel electrical: Paddle Shifter Install - Paddles and Steering Wheel Connections

And here's a link to Raymond's site from where you can download schematic and instructions: http://www.wlsmithelectronics.com/page2.php

===========================================

Before we get started, the background and acknowledgments:

This wiring kit is used to install a set of paddle shifters onto your steering wheel, which act the same as the auto-stick lever. You have one paddle for upshift and one for downshift. They operate exactly like your shift lever, once the transmission is in Drive.

The combination of these three fellas coming together really made this whole thing do-able.

Anthony (atwong1) found a source for these paddles, when nobody else could find them in quantity, at least not for a good price.

Jim (jaak) discovered the spare contacts in the clockspring, which made it so you no longer needed the receiver/transmitter.

Raymond (plcman) made the harnesses plug-and-play, and incorporated a line-lock option.

===============================================

The quick recap:

Here's the paddle install write-up thread (which was done before the harnesses were available, and back when we thought these paddles were only good as alternatives for the ShiftHammer buttons - at the time you still needed the ShiftHammer transmitter/Receiver combo). It mostly still applies - it's how to install the paddles, not the wiring:

How to install the AMG Shift Paddles on our LX's

Here's where this thing broke WIDE OPEN. Jim (jaak) figured out that there were spare (unused) terminals inside the steering wheel, which allows you to pass two circuits through (one for each shift paddle) - and then wire it directly to the factory wiring harness - no transmitter necessary! All you need is some wire, essentially:

Direct Wired Paddle Shifters

Then Raymond (plcman) said, well, shoot - I'll do you one better - instead of tapping and splicing down there at the shifter mechanism, why not make it plug-and-play? All the connectors the factory uses are commonly available (if you know where to look), so let me rig up some harnesses:

Ultimate--Paddle Jaak Hack wiring kit!

It got even more creative and impressive, but you need to read that one yourself. Most of it's consolidated in the first post.

DaddyGoFast did a great write-up that shows really clearly how to do the connections in the steering wheel, so I skipped that part:

HOW TO W/Pics: Paddle (or in my case button) shifter install -DGF N00b style

Here's the thread about the trouble with the '08 models:

URGENT: Please help atwong1 with ShiftHammer installation

You'll need to have this handy:

How to Remove/Change your Steering Wheel

Here's the current Group Buy for the paddles:

Ultimate Stealth Paddle for ShiftHammer Group Buy Round 3

Also, I want to thank Pete (fnkychkn) for always helping get things right - couldn't do them without Pete's help.

========================================

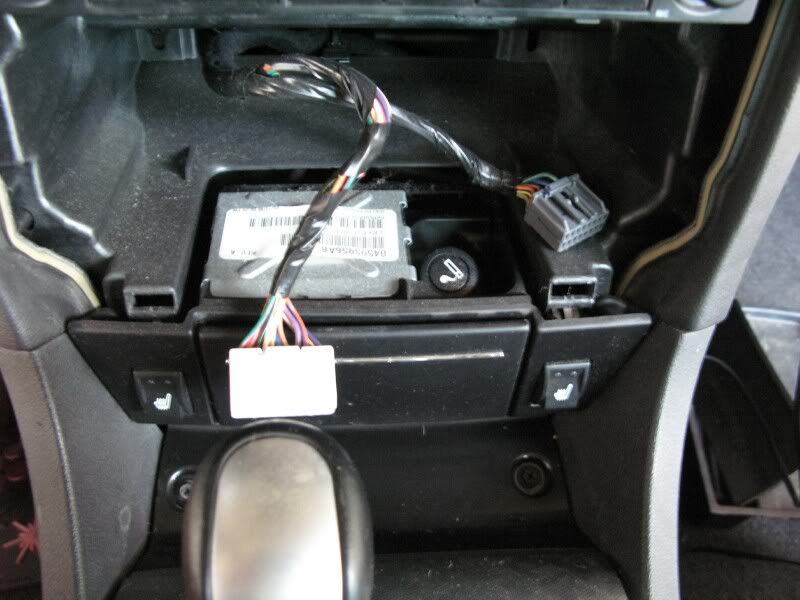

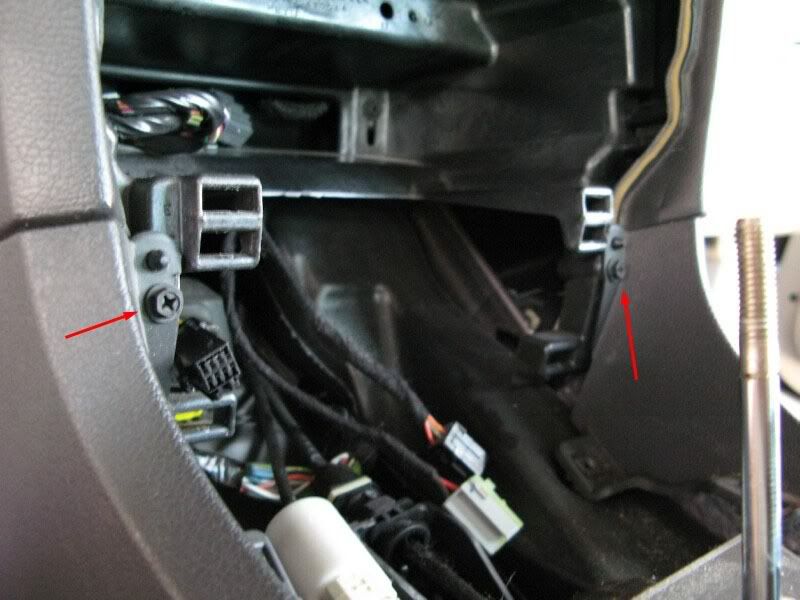

First off, here's what you'll need:

![Image]()

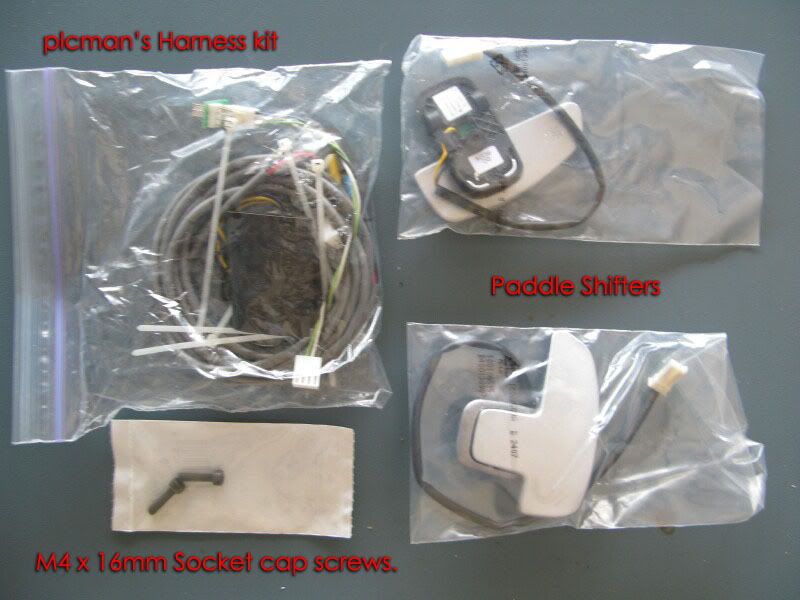

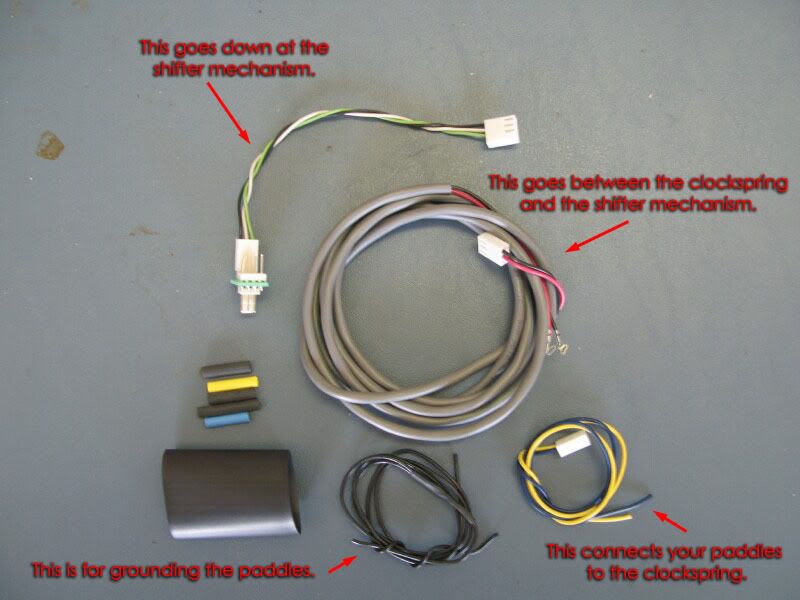

Here's the contents of the Harness kit:

![Image]()

Next Post, Preparation and Disassembly.

Included are instructions for the simple adapter board kit, but soon I should be able to add instructions for the lockout and line-lock kits.

UPDATE: Here's the link to my Paddle Install thread, with info on all the steering wheel electrical: Paddle Shifter Install - Paddles and Steering Wheel Connections

And here's a link to Raymond's site from where you can download schematic and instructions: http://www.wlsmithelectronics.com/page2.php

===========================================

Before we get started, the background and acknowledgments:

This wiring kit is used to install a set of paddle shifters onto your steering wheel, which act the same as the auto-stick lever. You have one paddle for upshift and one for downshift. They operate exactly like your shift lever, once the transmission is in Drive.

The combination of these three fellas coming together really made this whole thing do-able.

Anthony (atwong1) found a source for these paddles, when nobody else could find them in quantity, at least not for a good price.

Jim (jaak) discovered the spare contacts in the clockspring, which made it so you no longer needed the receiver/transmitter.

Raymond (plcman) made the harnesses plug-and-play, and incorporated a line-lock option.

===============================================

The quick recap:

Here's the paddle install write-up thread (which was done before the harnesses were available, and back when we thought these paddles were only good as alternatives for the ShiftHammer buttons - at the time you still needed the ShiftHammer transmitter/Receiver combo). It mostly still applies - it's how to install the paddles, not the wiring:

How to install the AMG Shift Paddles on our LX's

Here's where this thing broke WIDE OPEN. Jim (jaak) figured out that there were spare (unused) terminals inside the steering wheel, which allows you to pass two circuits through (one for each shift paddle) - and then wire it directly to the factory wiring harness - no transmitter necessary! All you need is some wire, essentially:

Direct Wired Paddle Shifters

Then Raymond (plcman) said, well, shoot - I'll do you one better - instead of tapping and splicing down there at the shifter mechanism, why not make it plug-and-play? All the connectors the factory uses are commonly available (if you know where to look), so let me rig up some harnesses:

Ultimate--Paddle Jaak Hack wiring kit!

It got even more creative and impressive, but you need to read that one yourself. Most of it's consolidated in the first post.

DaddyGoFast did a great write-up that shows really clearly how to do the connections in the steering wheel, so I skipped that part:

HOW TO W/Pics: Paddle (or in my case button) shifter install -DGF N00b style

Here's the thread about the trouble with the '08 models:

URGENT: Please help atwong1 with ShiftHammer installation

You'll need to have this handy:

How to Remove/Change your Steering Wheel

Here's the current Group Buy for the paddles:

Ultimate Stealth Paddle for ShiftHammer Group Buy Round 3

Also, I want to thank Pete (fnkychkn) for always helping get things right - couldn't do them without Pete's help.

========================================

First off, here's what you'll need:

Here's the contents of the Harness kit:

Next Post, Preparation and Disassembly.